Can This Toxin In Our Drinking Water Solve Our Energy Crisis?

Imagine a global health crisis that silently affects millions, poisoning the very source of life we depend on: groundwater. Now, imagine the solution to this problem—the sludge, the toxic waste byproduct of cleaning that water—isn't just a headache to dispose of, but is actually a hidden gold mine.

This isn't science fiction; it's the reality uncovered by groundbreaking research: a powerful new technology that transforms carcinogenic arsenic waste into a critical raw material essential for the digital age.

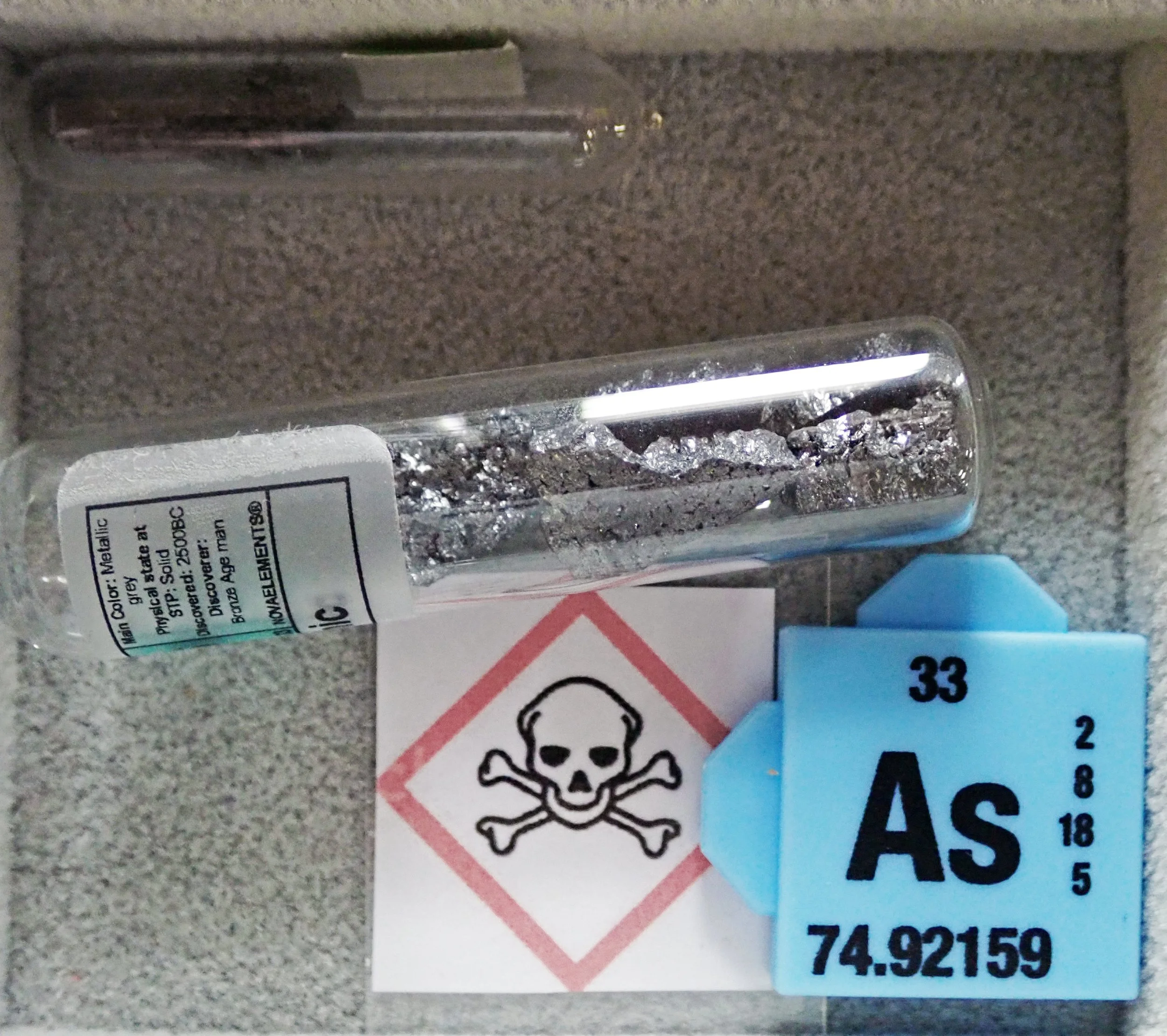

For decades, arsenic has been synonymous with poison, a notorious carcinogen lurking in the world’s aquifers. But times have changed. This study, published in Science Advances, details a revolutionary two-stage process of "commodifying a carcinogen".

Researchers have figured out how to extract nearly all the arsenic from water treatment sludge and—in an astonishing chemical feat—convert it into pure, amorphous metallic arsenic nanoparticles.

This is more than just an environmental win. It’s an economic disruptor for the water sector, offering a way for treatment facilities to generate revenue by producing a material critical for semiconductors, 5G technology, and the future of clean energy. This one discovery could fundamentally change how we finance clean water, manage toxic waste, and source the high-tech materials that power modern life.

Why Arsenic Is the World’s Silent Threat

Arsenic poisoning

To appreciate the genius of this new process, you first have to understand the scale of the arsenic problem.

Arsenic is a naturally occurring element, often released into groundwater when minerals in the earth’s crust dissolve. It is colorless, odorless, and tasteless, making it a truly insidious contaminant.

While it occurs globally, the most high-profile crises are concentrated in regions like South Asia (Bangladesh, India), parts of the US (the Southwest), and specific areas in South America and China.

The reason it is such an urgent public health threat is simple: arsenic is a potent carcinogen. Long-term exposure, even to low levels, is linked to a devastating array of health issues, including:

Skin lesions and cancer: The earliest and most visible signs of chronic poisoning.

Internal Cancers: Including bladder, lung, kidney, and liver cancer.

Cardiovascular disease and neurological problems.

It is estimated that hundreds of millions of people worldwide are exposed to unsafe levels of arsenic in their drinking water, a public health burden that costs billions in health care and lost productivity. The World Health Organization (WHO) sets the maximum safe limit at 10 micrograms per liter, but in some affected regions, concentrations can be many times higher than this.

A Legacy of Toxic Waste

When communities decide to treat arsenic-contaminated water—a massive undertaking in itself—they typically employ methods that use adsorbents, often iron oxyhydroxides (Fe-oxyhydroxides), to “catch” the arsenic. These materials act like sponges, pulling the arsenic out of the water.

This is where the second major problem begins. Once the sponge is full, it has to be replaced, creating a new, highly concentrated waste material—a thick, brown, arsenic-rich “sludge” or solid by-product.

This waste is classified as hazardous. You can’t just dump it. It requires specialized, expensive disposal methods, often involving burial in secure, lined landfills to prevent the arsenic from leaching back into the environment - a literal toxic vat.

The cost of disposing of this toxic waste adds significantly to the overall expense of clean water treatment. This economic burden is particularly crippling for marginalized, low-income communities that are often the hardest hit by arsenic contamination. The need to dispose of the sludge often makes effective, continuous water treatment financially unsustainable.

We are stuck in a loop: we solve the water crisis by creating a waste crisis, which in turn makes the water crisis too expensive to solve permanently.

The research directly addresses this unsustainable model by asking a revolutionary question: What if the waste itself was worth more than the cost of disposal?

From Poison to Critical Raw Material

The world of high-tech manufacturing has breathed new life into this old poison.

In a stunning reversal of fortunes, the element arsenic is experiencing a genuine “renaissance”. Over the last few years, major economic blocs, including the United States and the European Union, have classified arsenic as a Critical Raw Material (CRM).

A CRM is a material that is economically and strategically important for a country or region, but which also has a high risk of supply disruption. If a material is crucial for manufacturing next-generation technology but is only mined in a few politically unstable areas, it’s a CRM.

The value of arsenic lies not in its toxic compounds, but in its pure metallic form: As(0).

Why is As(0) Now Essential?

Digital Infrastructure: Metallic arsenic is a key ingredient in the semiconductor material Gallium Arsenide (GaAs). GaAs chips are faster and can operate at higher temperatures than traditional silicon chips, making them indispensable for 5G network components, satellite communications, and high-speed computing.

Clean Energy: GaAs is also used in high-efficiency solar cells, particularly those used in concentrated photovoltaics and aerospace applications.

Supply Chain Security: The current supply chain for As(0) is fragile. It relies almost entirely on refining arsenic-containing metal ores, often as a side-product of copper or gold mining. Creating a new, independent source from water treatment waste offers a path to greater supply chain security and sustainability.

From Waste to Nanoparticle

The core of this disruptive technology is a unique two-stage chemical process that extracts arsenic from the sludge and then purifies it into a usable, high-tech material: pure amorphous As(0) nanoparticles.

Think of the arsenic-rich sludge—the Fe-oxyhydroxide adsorbent—as a super-dense, toxic metal sponge. The arsenic is chemically locked inside the structure of the iron. The first challenge is to unlock it.

The researchers use a high-pH (alkaline) solution, such as one with a pH of around 11.5, to literally peel the arsenic away from the iron. This process is highly selective and incredibly effective.

The alkali extraction step successfully solubilized 96.5 ± 0.6% of the total arsenic content from the sample waste material.

This statistic is a game-changer. It means the researchers managed to capture virtually all of the arsenic, leaving behind a significantly less hazardous, de-arsenified iron matrix (the sponge) that is much easier and cheaper to dispose of. Crucially, this creates a concentrated, pure liquid feedstock ready for the final conversion.

With the arsenic now dissolved in the alkaline solution, the next step is the actual chemical magic: turning the toxic, dissolved arsenic into pure, metallic, zero-valent arsenic [As(0)].

The researchers employed a technique called selective reduction. They use an electrochemical process—essentially using electricity—to trigger a chemical reaction that forces the arsenic to change its chemical state.

The selective part is crucial. In the extracted solution, the arsenic exists as arsenate and arsenite (As(V) and As(III), respectively)—the toxic, soluble forms. The electrical current is precisely controlled to "reduce" only the arsenic compounds.

The final product was astonishingly pure, containing 99.5 ± 0.3 wt % arsenic. This level of purity is necessary for high-tech applications like semiconductors. The final product is amorphous, meaning its atomic structure is disordered, unlike crystalline structures. Amorphous materials often have unique properties that are highly desirable in electronic devices.

The arsenic forms tiny nanospheres with diameters ranging from 10 to 50 nm (nanometers). Nanoparticles are key to materials science because their small size gives them unique physical and chemical properties that bulk materials do not possess.

Why Do We Care?

This disruptive technology promises a rare “triple bottom line” win—benefiting people, the planet, and profit simultaneously.

For the water treatment sector, the potential economic upside is transformative. Currently, treating arsenic-contaminated water is a cost center. It requires expensive materials and creates expensive waste. If a treatment facility can implement this new technology, it shifts its financial model. The revenue generated from selling high-purity As(0) nanoparticles can be used to dramatically offset the cost of water treatment.

In marginalized regions where clean water is often unaffordable, generating revenue from the waste product could provide a sustainable funding mechanism, turning a public health charity case into an economically viable operation. The value of the recovered arsenic can turn a financially challenging water treatment plan into an economically sustainable one.

The environmental benefits are straightforward and immense. The technology transforms a hazardous waste stream—the toxic sludge—into a revenue stream. By extracting almost all of the arsenic (96.5%), the volume and toxicity of the final residual waste are drastically reduced. The remaining iron matrix is far less dangerous and easier to manage, reducing the risk of environmental contamination and the high cost of securing hazardous waste landfills.

The discovery creates a completely new, environmentally sound source for a Critical Raw Materials. The conventional method of obtaining metallic arsenic is environmentally intensive and geographically concentrated. By creating a pathway to source As(0) from decentralized water treatment facilities around the globe, this technology introduces robustness and stability to the international supply chain for advanced electronics. This makes the digital and clean energy sectors less vulnerable to geopolitical risks associated with mining.